Using the Scarf Joint to Gain Length in Your Timber Frame

The scarf joint lets you join the shorter pieces together to make longer ones, using a strong and reliable joint. There are probably many more elegant ways to make this joint, but here is a "rude and crude" real-world working shop method. First, make a sled jig for your band saw. Then, make the long slanted cuts on the band saw.

Using the Scarf Joint to Gain Length in Your Timber Frame

In this paper, various forms of scarf and splice joints connecting elements in timber structures are presented as these were developed over the years. The development of joints geometry has been associated with their static behaviour.

Scarf Joint Timber Frame HQ

The method known as "scarfing" is used for the joining of timber in the direction of its length, enabling the workman to produce a joint with a smooth or flush appearance on all its faces.

Joint Venture Ep. 16 Undersquinted wedged scarf joint (Western Joinery) YouTube

Making Scarf Joins. All craftspeople appreciate a tight timber joint. Watch our instructional video on the creating the perfect scarf joint. In this video we show you when and how to create scarf joins using Abodo timber weatherboards. How to create the perfect scarf joint - by Abodo Wood.

Timber Framing Joining Big Timbers Scarf Joint YouTube

A scarf was used to join stem and stern timbers to a center keel. Dozens of scarf joints have been documented over time. Some have failed miserably, while others have survived centuries. The double-bladed scarf, first introduced in the 16th century, is the strongest joint for joining two timbers.

Scarf woodworking joints CRAFTSMANSPACE

For timber framers, scarf joints are the answer. On the end of two plates, a mirror imaged, angled half lap joint is cut. Typically about 3′ long and cut at approximately 66 degrees, the scarfs have mortice and tenon joints on each end. Two Ash or Oak pegs securely hold the two planes together.

StopSplayed Scarf Joint with Wedges 2 Kenai Timber Frames

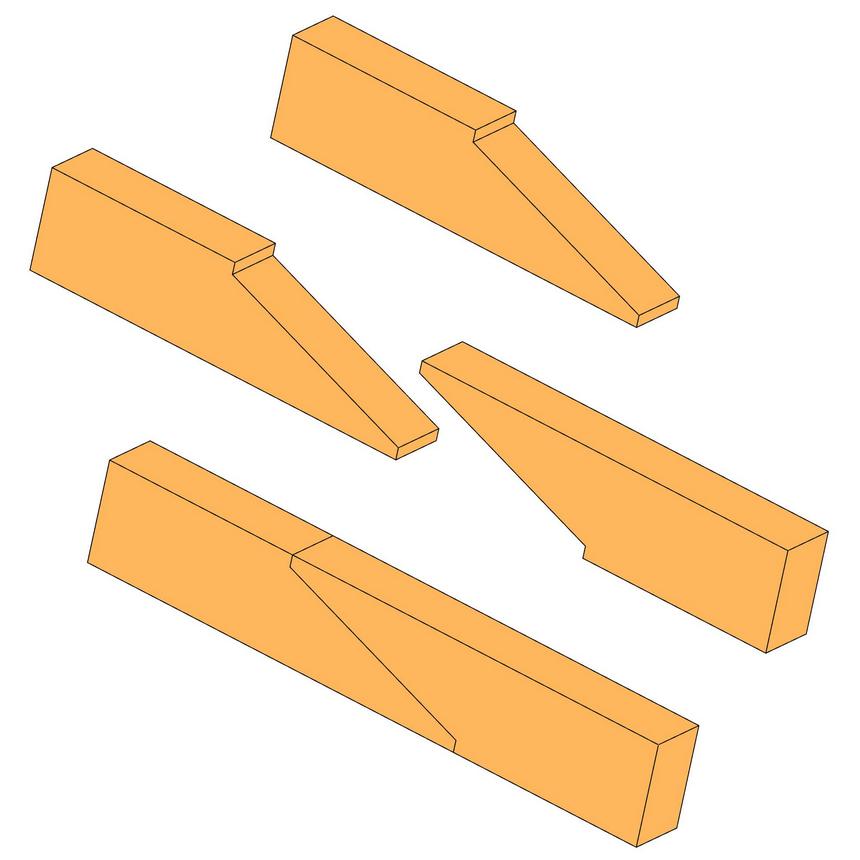

A scarf joint connects two timbers together to make one. There are many various ways to cut scarf joints. The one shown above has become VTWs favorite over time because the integrity of the joint holds up well after the timber shrinks, unlike some other ways to cut them. A general rule is the length of the scarf should be at least 3x the height.

StopSplayed Scarf Joint with Wedges Kenai Timber Frames

The Scarf Joint: THE HINGED JOINT. The method known as "scarfing" is used for the joining of timber in the direction of its length, enabling the workman to produce a joint with a smooth or flush appearance on all its faces. One of the simplest forms of scarfed joint is known as the half lap, in which a portion is cut out at the end of each beam.

How to cut a Scarf Joint, Time Lapse The Samurai Carpenter

A scarf joint, or scarph joint, is a method of joining two members end to end in woodworking or metalworking. [1] The scarf joint is used when the material being joined is not available in the length required.

Using the Scarf Joint to Gain Length in Your Timber Frame

Scarf Joint Explore our comprehensive guide on scarf joints, the key solution in timber framing for extending lumber lengths. Discover various scarf joints, like the Stop-Splayed Scarf Joint with Sallied Abutments and Half Lap Scarf Joint, each providing unique structural benefits and aesthetic appeal.

Half and Bridled Scarf Joint Timber Frame HQ Timber frame construction, Timber frame

Hamill Creek | Jun 15, 2020 In timber frame construction, a scarf joint (also known as a splice joint) joins two pieces of wood, when individually they aren't long enough for the desired purpose. Notches are cut so that the pieces fit snugly and smoothly together like a jigsaw puzzle.

Timber Framing Scarf Joint YouTube

1) Strength - A scarf joint is surprisingly powerful and can stand up to a range of forces, suitable for furniture that needs to withstand regular use. 2) Appearance - The scarf joint is simple and elegant, with no visible fasteners. This is ideal for pieces that need a clean and finished look.

A Timber Frame Scarf Joint 3 Steps (with Pictures)

Shown with the scarf joint centered in the knee brace. While not as common now in engineered frames, a few 1″ pegs could be used or simply using the wedge will do. While this is an easier and cheaper way to handle this connection, this method does not perform as well in holding the joint together as the other two methods.

japanesescarfjointthomsontimberscotlandlarge Thomson Timber

Putting together the sill timbers of our timber frame workshop, showing how our bridled/halved scarf joint, as well as housed mortise and tenon joints.https:.

Half and Bridled Scarf Joint Timber Frame HQ

Half Lap Scarf Joint. Like other joints of its kind, a half-lap scarf joint is used to join two timbers end-to-end to span a length greater than the lumber at hand. The half-lap is probably the simplest of all the scarf joints to cut, as it is merely two timbers reduced to half of their thickness where they lap over each other.

Stop Splayed Scarf Joint Timber Frame HQ

Scarf Joint. Also called the "Splice Joint," this is a lesser-used joinery technique in Timber Framing. This method involves notches being cut into two pieces of Timber which are then fitted together end to end and secured with a peg in the center of the connection.